Ayush Wilson, Assistant Professor, Department of Optometry, SHS, Sushant University

The field of contact lenses has witnessed remarkable advancements in recent years, transforming not only vision correction but also ocular health monitoring and therapeutic applications. India, with its growing eye care industry, is embracing these innovations, making advanced contact lenses more accessible to patients. As an optometrist and educator, I am excited to explore how these cutting-edge lenses are reshaping the future of vision care in India.

The Evolution of Contact Lenses

Contact lenses have evolved significantly since their inception, moving beyond simple refractive correction to specialized applications. Traditional soft and rigid gas-permeable (RGP) lenses have now been supplemented by technologically advanced options, offering improved comfort, visual performance, and ocular health benefits.

Recent Advancements in Contact Lens Technology

1. Custom Scleral and Hybrid Lenses

Scleral lenses, which vault over the cornea and rest on the sclera, have revolutionized vision correction for patients with keratoconus, irregular corneas, and post-surgical conditions. Hybrid lenses, combining the benefits of rigid and soft lenses, offer superior visual clarity with enhanced comfort. The growing availability of these lenses in India is improving treatment options for patients with complex corneal conditions.

2. Multifocal and Extended Depth-of-Focus (EDOF) Lenses

With an aging population and increasing cases of presbyopia, multifocal and EDOF contact lenses provide an effective alternative to reading glasses and bifocals. These lenses enhance near, intermediate, and distance vision while minimizing visual disturbances, catering to the lifestyle needs of Indian professionals and elderly patients.

3. Smart and Biosensing Contact Lenses

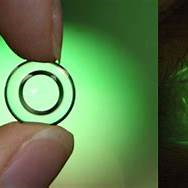

One of the most groundbreaking innovations is the emergence of smart contact lenses embedded with biosensors. These lenses can monitor intraocular pressure (IOP) in glaucoma patients, track glucose levels for diabetics, and even provide augmented reality (AR) functionalities. While still in early stages, global research on smart lenses is paving the way for their future adoption in India.

lenses embedded with biosensors. These lenses can monitor intraocular pressure (IOP) in glaucoma patients, track glucose levels for diabetics, and even provide augmented reality (AR) functionalities. While still in early stages, global research on smart lenses is paving the way for their future adoption in India.

4. Drug-Delivery Contact Lenses

Conventional eye drops have limitations in drug absorption and patient compliance. Drug-eluting contact lenses are being developed to provide sustained release of medication for conditions such as dry eye, allergies, and glaucoma. As pharmaceutical and contact lens companies in India collaborate, we can expect these innovations to become more widely available.

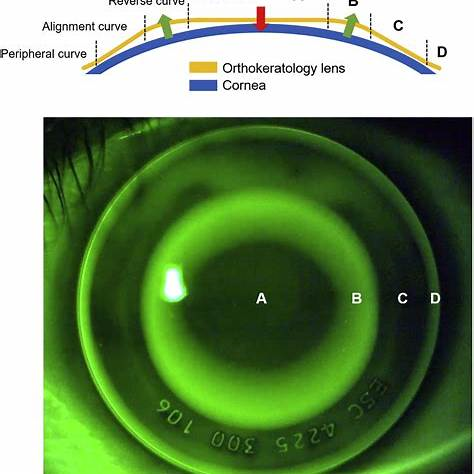

5. Orthokeratology (Ortho-K) Lenses for Myopia Control

With myopia prevalence on the rise, particularly among children, Ortho-K lenses offer a non-surgical solution to slow down myopia progression. These specially designed rigid lenses reshape the cornea overnight, allowing clear daytime vision without the need for glasses or daytime contact lenses. More Indian eye care practitioners are now incorporating Ortho-K into their practice, providing a promising intervention for childhood myopia management.

With myopia prevalence on the rise, particularly among children, Ortho-K lenses offer a non-surgical solution to slow down myopia progression. These specially designed rigid lenses reshape the cornea overnight, allowing clear daytime vision without the need for glasses or daytime contact lenses. More Indian eye care practitioners are now incorporating Ortho-K into their practice, providing a promising intervention for childhood myopia management.

Manufacturing of Advanced Contact Lenses

The manufacturing of advanced contact lenses involves precision engineering and biocompatible materials to ensure optimal comfort and vision correction. The key steps in manufacturing include:

- Material Selection:

Soft lenses are made from hydrogel or silicone hydrogel, while RGP and scleral lenses use durable oxygen-permeable polymers.

- Molding and Lathing:

Soft lenses are typically manufactured using cast molding, while custom lenses like scleral or Ortho-K lenses are created using precision lathing techniques.

- Surface Treatments:

Advanced coatings and plasma treatments enhance wettability, oxygen permeability, and resistance to deposits, improving comfort and lens longevity.

- Quality Control:

Every lens undergoes rigorous optical quality and biocompatibility testing before reaching the patient.

Role of AI in Customizing Contact Lenses

Artificial intelligence is playing a crucial role in the customization and optimization of contact lenses, leading to improved patient outcomes. AI contributes to:

- Precision Fit and Design:

AI-driven topography analysis enables the creation of lenses tailored to an individual’s corneal shape, improving comfort and visual performance.

- Predictive Analytics for Myopia Control:

AI models can analyze patient data to predict myopia progression and recommend personalized Ortho-K or multifocal lens designs.

- Automated Quality Control:

Machine learning algorithms enhance quality control by detecting microscopic defects in lenses, ensuring high manufacturing standards.

- Smart Lenses with AI Integration:

AI-powered biosensors embedded in lenses can provide real-time health monitoring, such as tracking tear film composition, eye strain, and intraocular pressure.

Challenges and Future Prospects in India

While these advancements present exciting opportunities, several challenges remain:

- Awareness and Accessibility:

Many patients and even practitioners in India are not fully aware of the potential benefits of advanced contact lenses. Educational initiatives are essential to bridge this gap.

- Cost and Affordability:

High-tech lenses often come at a premium price, limiting their reach to urban populations. Efforts to reduce manufacturing costs and include these lenses in insurance coverage will be critical.

- Regulatory Approvals:

Ensuring the safety and efficacy of novel lenses through clinical trials and regulatory approvals is vital for widespread adoption.

Advanced Contact Lenses in India: Manufacturing & AI-Driven Customization

India’s contact lens industry is evolving rapidly, driven by advancements in material science, precision manufacturing, and AI-based customization. Specialized lenses, such as scleral, orthokeratology (ortho-K), and hybrid lenses, are becoming more accessible. AI is playing a critical role in optimizing lens design, ensuring a precise fit, and enhancing user comfort.

Manufacturing of Advanced Contact Lenses

The production of contact lenses involves a multi-step process, combining material innovation, high-precision machining, and rigorous quality control.

1. Material Selection

Contact lens materials are chosen based on oxygen permeability, durability, and comfort. The most commonly used materials include:

- Silicone Hydrogel:

Offers high oxygen transmission, reducing dryness and irritation.

- Rigid Gas Permeable (RGP) Polymers:

Used in custom-fit lenses like scleral and ortho-K lenses, providing superior optical clarity.

- Hybrid Materials:

Combine soft lens comfort with the optical performance of RGP lenses.

2. Lens Manufacturing Techniques

Contact lenses are manufactured using various high-precision techniques:

A. Spin Casting (for Soft Lenses)

- A liquid monomer is spun at high speeds in a mold, shaping the lens through centrifugal force.

- The lens is then polymerized using UV light or heat.

- Used for mass production of daily disposable and soft lenses.

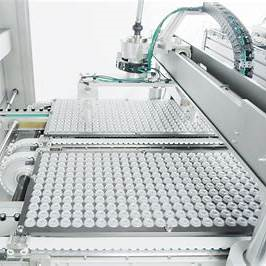

B. Injection Molding (for Mass Production)

- Molten lens material is injected into precision molds.

- The material is cured, cooled, and shaped.

- Highly efficient for high-volume soft lens production.

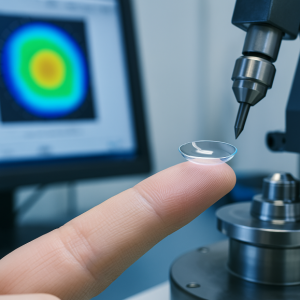

C. Computer-Controlled Lathing (for Custom Lenses)

-

CNC (computer numerical control) lathes shape rigid, scleral, and hybrid lenses with micrometer precision.

-

After shaping, lenses are polished to achieve smooth, optically clear surfaces.

-

Ideal for specialty lenses like scleral and ortho-K lenses.

3. Surface Treatment & Coatings

- Plasma Treatment: Enhances wettability and reduces protein deposits.

- UV & Blue Light Filters: Protect against harmful light exposure.

- Anti-Reflective Coatings: Improve optical performance and reduce glare.

4. Quality Control & Sterilization

- Lenses undergo precision testing to ensure power accuracy, thickness consistency, and edge smoothness.

- Automated inspection systems detect micro-defects.

- Lenses are sterilized using UV radiation or autoclaving before packaging.

The Role of AI in Customizing Contact Lenses

Artificial intelligence is revolutionizing how contact lenses are designed, fitted, and personalized for individual users. AI-driven technologies enhance both diagnostic precision and manufacturing efficiency.

1. AI-Based Corneal Mapping & Lens Design

- AI-powered topographers analyze corneal curvature and detect irregularities such as keratoconus or astigmatism.

- Deep learning models generate precise contact lens prescriptions by analyzing thousands of corneal maps, reducing trial-and-error fittings.

- AI optimizes scleral lens vault, ensuring proper clearance over the cornea.

2. AI-Driven Ortho-K Lens Optimization

-

- AI assesses overnight corneal reshaping patterns and refines ortho-K lens designs.

- Predictive modelling improves treatment outcomes for myopia control.

3. AI in Soft Contact Lens Customization

-

- AI algorithms analyze tear film quality, helping to design moisture-retaining lenses for dry eye patients.

- Adaptive lens designs based on real-time eye movement tracking improve lens stability and comfort.

4. Smart Contact Lenses & AI Integration

-

- AI-assisted glucose-monitoring lenses are being developed for diabetic patients.

- AR-enabled lenses use AI for augmented reality applications, such as real-time navigation.

The Future of AI in Contact Lens Manufacturing

AI will continue to shape the contact lens industry in India through:

✅ Automated real-time lens fitting simulations.

✅ AI-driven quality control, reducing manufacturing defects.

✅ Smart lenses for drug delivery and biosensing applications.

India is at the forefront of adopting AI-enhanced eye care solutions, making contact lenses more personalized, effective, and accessible. As technology advances, the combination of AI and precision manufacturing will set new standards for vision correction.